GENERAL CHARACTERISTICS:

Air tubular armored tubular resistances are indicated for use in infinite industrial and civil applications.

These products are ideally suited to a wide range of applications and shapes wherever it is required to heat air and / or metal masses in heat dissipation, with the advantage of being able to be adapted locally and on – insertion into the available space or the mold cavity that will need to accommodate them.

Hence, the need to create high quality, reliability, durability, versatility and performance heaters, in compliance with the strictest safety and care requirements.

Flexible air tubular resistors can in fact take on countless shapes and folds and their compact size makes it suitable for both direct and indirect air heating.

The use of high-quality materials within our production cycle enables flexible tubular electric armatures to achieve high performance.

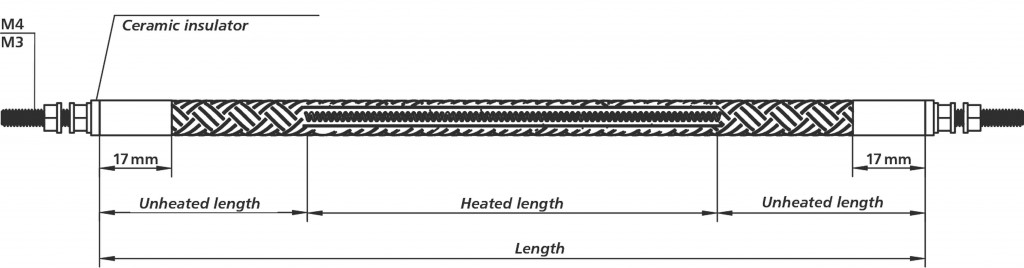

The outer casing is made of pure Nickel metal braid (diameter 6,5 mm, 8,0 mm, 8,5 mm, 10 mm), able to adapt to each curve, adhering fully to each curve and / or bend and engaging perfectly in the surface of the host groove without leaving any free interstitial and / or air gap; this allows this type of flexible resistors to guarantee maximum thermal exchange even when subjected to particularly high mechanical stresses.

Typically, this type of resistance has a power density of between 8 and 9.5 W / cm2; density, this, compatible with the only application in heating contact with heat dissipation. However, direct heating of air requires much lower power density to be assessed from time to time, depending on the technical-application specifications indicated by the customer.

Below we summarize some of the main features of this type of flexible tubular resistors:

On request, this type of resistance can be subjected to a finishing cycle with a special sealant surface treatment to prevent accidental penetration of liquids and / or gases (for example, moisture or oil). This special sealer is able to withstand maximum temperatures. 350 ° C.

TYPICAL APPLICATIONS

The entire production cycle of flexible tubular resistors is subjected to the most rigid dimensional and electrical tests in accordance with our ISO 9001: 2008 certified quality management system and in full compliance with CEI / EN standards.

Among the main tests on electrical testing, this type of product is carefully tested for insulation resistance, dielectric strength, ohmic value and leakage current.

Our range of flexible tubular resistors meets the requirements of EN 60335-1 for electrical equipment safety.

In spite of this, we always recommend that the end user strictly observe the local regulations required for the installation and wiring of the electrical power resistors.