GENERAL CHARACTERISTICS:

GENERAL CHARACTERISTICS:

They are called superheaters for air and steam that heat and heat a temperature above 350 ° C.

They are required to meet the most varied industrial conditions of heating gaseous fluids, air or gas mixtures.

This type of heaters guarantees high performance and efficiency in maintaining high volumes of steam in forced circulation with open loop or in closed circuit.

The heating elements that make up the tube bundle can take U-shaped, eyelet or twisted forms. This type of air and gas superheaters is intended for horizontal and vertical installation, in direct heating of forced air and / or gases; the state is guaranteed by the use of spacers appropriately ee and cut a laser to minimize any loss of load (in mmH2O), so as to obtain the output of the heat produced inside them, avoiding dangerous, special heat accumulations at the high surface temperatures reached, which can easily be drained by means of valves or pressure switches affixed to suitable auxiliary nozzles (see details in the appropriate section of pressure gauges and valves in the “temperature control” category).

TECHNICAL DATA

To guarantee the design of an efficient air / gas superheater it is necessary to know the following technical parameters:

The armored heating elements installed on board these special heaters are, moreover, designed and positioned with a precise lay-out, in order to make the heat exchange optimal.

Each element is welded to TIG or brazed in silver alloy on unified DIN flanges, ANSI, or on flanged connections of non-unified size of variable size depending on the working pressure and the working temperature.

The temperature of the leather on the elements depends on the outlet temperature required by the specific application and on the permissible surface load (W / cm²) as well as, naturally, the type of fluid to be heated and its speed, measured in meters per second (m / s) or in cubic meters / hour (m3 / h).

The head of the electrical connections is the area most stressed by the application to which these heaters are subjected, which is why the connection head is always kept at a reasonable distance from the process connection flange (neutral cooling extension).

We are able to produce CE-certified air superheaters, made in full compliance with the recent CEI and CENELEC and PED 97/23 / CE regulations.

This type of process superheaters is made of high quality materials with regard to the heating tube bundle, made of very high quality material also with regard to the tubular sheath, able to withstand the maximum operating temperatures (Stainless Steel AISI316L, AISI316L SS , Incoloy800 and Incoloy825), as well as the material of the pressurized tank that houses the tube bundle, exclusively in high temperature steel, extruded SS type AISI316.

The power can be concentrated in one or more power stages with the respective on board tested inputs of the gas, metric, BSP, NPT or Gk step connections. also adopted for the independent power supply of the temperature control devices installed on board the heater

Typical Uses

CERTIFIED QUALITY PRODUCT

The entire production cycle of our superheaters or electric superheaters for air / gas / steam is subjected to the most rigorous dimensional checks and electrical tests in accordance with the regulations of our Company Quality System certified ISO 9001: 2008 and in full compliance with the requirements of CEI / EN current standards.

TECHNICAL DATA

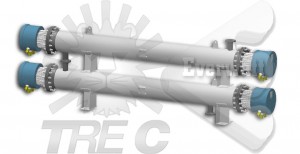

Depending on the specific temperature and the air flow to be heated, it is possible to configure the design of the electric heat exchanger composed of one or more pressurized tanks (also suitably insulated) connected in series with each other and by one or more heads placed side by side or placed on each other. end of the coat as illustrated below:

|

|

|

The family of superheaters of our production is suitably equipped with efficient thermoregulation devices (control thermostats with adjustable temperature scale, automatic or manual reset or, alternatively, leather safety thermostats with cut-out intervention, PT100o thermoresistances and / o “K”, “N” or “S” thermocouples, suitable to protect the heater from the risk of excessive overheating.

On board the head of the electrical connections, according to the specific needs of the customer, the power supply inputs (NPT or GAS) are appropriately sized based on the number of installed elements, power and amperage that determines the cable cross-section .

SOME EXAMPLES: