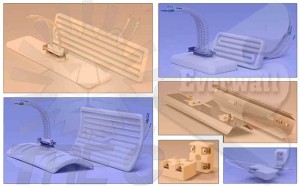

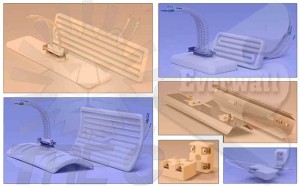

Everwatt Ceramic Infrared heaters production range have been designed and engineered to get the best performances and infrared output.

Molti materiali plastici ed altre tipologie di materiali assorbono onde infrarossi, il che fa dei riscaldatori ceramici infrarossi una delle più efficienti sorgenti radianti di onde infrarossi. Inoltre, a supporto di questi riscaldatori, un ampio range di riflettori in acciaio alluminizzato assicura che la maggior parte della radiazione infrarossi generata dal riscaldatore venga riflessa in avanti verso l’area o superficie da riscaldare.

Most of our products are already available on stock.

Technical features

- Temperature (range): 300 ° C / 700 ° C (572 ° F / 1292 ° F)

- Useful infrared Wavelenght (range): 2/10 microns

- Fe-Cr / Al resistance wire

- Heater supplied voltage (range): standard @ 230V (other voltages available upon specific request)

- Power range: 125/150/200/250/300/325/400/500/650/750 / 1000W

- Standard dimensions: 245x60x31 mm | 122x60x31 mm | 60x60x31 mm

- Special dimensions: 245×110 mm (1000W-1500W) 60x60x40 mm (150W-250W)

- Mean surface temperature range: 262 ° C / 722 ° C

- Max working temperature: 750 ° C

- Watts density range: 9kW / m² (5.8W / in²) / 60kW / m² (38.7W / in²)

- Useful wavelength range: 2/10 μm

- Recommended radiation distance from heater: 100 to 200 mm

- Standard finishing: supplied with 100 mm L-shaped cables, insulated with steatite ceramic beads.

- The ability to equip the infrared ceramic heater with a thermocouple K (standard version with thermocouple) with positive pole (+) nickel-chrome (NiCr) material and positive pole (-) in Nickel-Aluminum (Ni-Al) material; Alternatively, on request, you can equip the infrared ceramic heater with a thermocouple “J”; the thermocouple must be connected to the thermoregulator by means of non-interconnected “K” type extension cables (which employ different metals that do not have the same electro-thermal characteristics) in compliance with IEC 60584.3 with a special green output (positive pole +) and white color (negative pole -)

TYPICAL JOBS:

Among the main uses of this type of infrared ceramic resistors, we find:

- Chemistry: Tunnel for Drying Paints, Inks and Resin Polymerization

- Plastic: electric oven for heat treatment of plastics (electric ovens for preheating, thermoforming and drying of granules and plastic laminates).

- Textile / Paper: Fabric Drying Ovens, Paper Drying

- Glass / Food-Conservation Industry: Ovens for pre-heating glass surfaces (drying and shrinking, sterilization, food heating, barbecue.

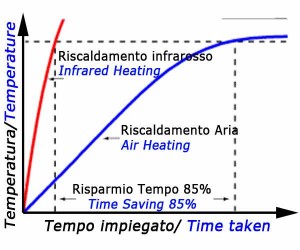

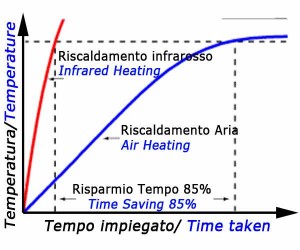

General characteristics and properties of infrared rays

The heat propagates by irradiation when the thermal energy is transmitted from a cold to a cold by means of electromagnetic waves called infrared waves, which are irradiated at the speed of light (3 x 10 cm / sec.), Similar to light radiations. The infrared rays produced by meeting a body, depending on the nature of the irradiated material, the quality of its surface and the wavelength of the radiation itself, give rise to refraction, reflection, absorption and diffusion. Of these radiations, only those with wavelengths between 2 and 4 microns (medium waves) have the highest penetration power in almost all substances.

STANDARD INFRARED HEATERS IN CATALOG

Where these infrared resistors are used in standard conditions, we have standard Various Potentiator heaters in both quartz and ceramic variants, mainly based on size, power supply and standard power.

SOME EXAMPLES: