Used as process and finishing electric heaters tool kits and, the THERMOREGULATION SKIDS are units used to transfer heat.

They are generally made up of:

Upon client’s specification, the thermoregulation skids are also supplied including auxiliary instruments, valves, pumps, exchangers.

“AD HOC” PERSONALIZED SYSTEMS for Electric Process Heaters, Continuous Heaters, Superheaters and Heat Exchangers

Always upon client’s specification, they can be equipped with electric panels for thermoregulation and process control, or through manual power variators, analogue or digital static power units SCR or P.I.D. controllers.

Their advanced product design employs precise timelines and directions, since the system is personalized according to the technical specifications and precise process exigences the system is foreseen for.

It is possible to manufacture thermoregulation skids in the non-dangerous environment version and in version for application in explosive environment, in explosive-proof configuration II2G EEx-d IIC / IIB (ATEX).

TECHNICAL DATA

SOME EXAMPLES:

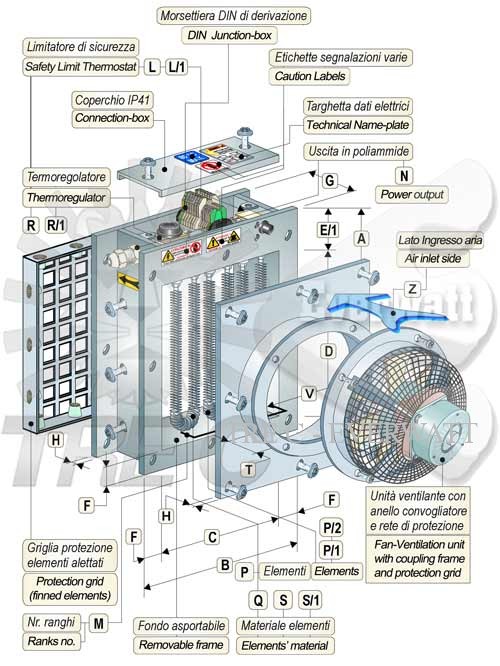

ELECTRIC AEROTHERMS & FAN-HEATERS for HVAC units (Air Duct Heaters for HVAC units and Air Conditioning Units + Coupling Convey Ring + Fan-Ventilation System)

These fan-heating units are composed with a fan-system engine enclosed with propeller and a cylindric convey ring.

Our Electrical Fan-Heaters (Aerotherms and Air Channel Duct Heaters) can be equipped with industrial ventilation fan-systems, as per what below summarized:

The range of application of such Air Ventilation Fan-heaters / Aerotherms is incredibly wide, with air delivery in the range from 120 to 250.000 m³/h, air pressures from 5 to 5000 kgf/m², with ventilation fan engines with nominal power from 0,18 to 500 kW and with propeller diameter from 160 to 1.600 mm., up to a diameter of 2.000 mm. for the most exigent applications.

Besides, we can design and manufacture special versions of such air ventilation fan-heaters / Aerotherms suitably applied to high temperature applications, abrasive dusts, inflammable and/or dangerous gases, etc.), either for material type or for specific application/design needs, in order to suit any of our custumer needs.

CERTIFIED QUALITY PRODUCT

The entire range of our electric aerotherms / fan-heating units is sturdy and fully reliable; these are built with high indisputable experience italian leading manufacturers’ fan-system engines, whose production cycles are certified and subject to the strictest technical-dimensional checks and electric tests in compliance with our own standards set forth ISO 9001:2015 certified Corporate Quality System and in full compliance with the latest european and international rules in force.

The construction and the documentation supplied to each electro-ventilation system is in compliance to European Directive Machine 89/392/CE and all electro-ventilators we’ve been applying to our Air heating units are exclusively marked “CE”.

SOME EXAMPLES:

|

|

“Main guide-lines for ventilation and aerolics”:

| KW = | LM x (T.OUT – T.IN) |

| 2500 |

| KW = | SCFM x (T.OUT – T.IN) |

| 2500 |

LM = Air Delivery (in L/min)

T.IN = Air Intake Temperature (°C) (normalmente pari a 20°C)

T.OUT = Air Outlet Temperature required (°C)

SCFM = Standard Cubic Feet per Minute = (Liters per min. / 28.3)

T.IN = Air Inlet Temperature (°F) (typically 70°F)

T.OUT = Required Air Outlet Temperature (°F)

The main figures which are typical of a fan-system are:

![]()