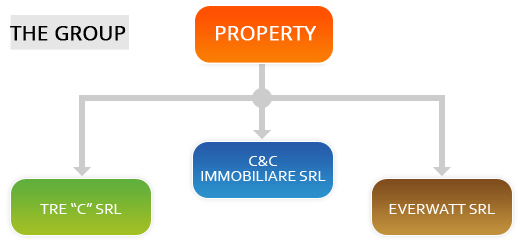

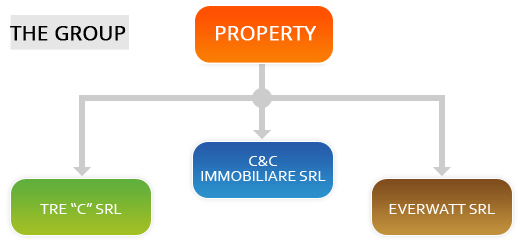

Our Group

Present since over 50 years on the national and international market, TRE “C” – EVERWATT Group manufactures heating electric elements

for many industrial and civil uses, in the economy’s all driving sectors, with utmost flexibility and attention to the Customer’s exigences, with quick and accurate deliveries and pre- and after-sale Technical Service.

Today, the typical production is constituted by electric heaters for the most different industrial applications, among them:

- Immersion Electric Heaters, used in most industrial sectors of the national and international economy and in plant engineering.

- Air heating finned immersion and Tubular Heaters

- Air Ducts Electric Heaters with Finned and Tubular heating elements, in standard version with electric connections housing IP40 – IP55 – IP65 – IP67 level, for Air Conditioning Units and (ATU) Air Treatment Units systems installations.

- Band heaters (used in the plastic sector machineries) in Ceramics and Mica.

- Nozzles heaters, Mica and Silicone Rubber Flat Heaters.

- Cartridge Heaters and Microtubular Heaters

- Single-pipe heaters for Fluids and Galvanic Baths and Galvanic thermal immersion heaters (AISI-316, Titanium, Pyrex, P.T.F.E. Politetrafluoroetilene).

- Ceramic and Silicone Rubber Drum heaters

- Flanged Electric heaters and Screw Plug-In heaters in Standard version with electric connectors housing IP40 – IP55 – IP65 – IP67 level and suitable for installation in hazardous environments, with Ex-proof connection headIP65 – E x-d IIB e IIC for temperature class T1-T6 II2G-ATEX.

- Air convectors and Anticondensation Air Ducts Electric Heaters with or without ATEX connection head (IP65 – E x-d IIB e IIC T1-T6 II2G-ATEX).

- Fluids, Air and Gas Process Heaters and Continous heat exchangers, enclosed with a pressurized vessel (with or without thermal insulation), made of AISI-304, AISI-321, AISI316, PED 97/23/CE certified, Cat. II – Mod. A1 CE 0100, Cat. IV CE and calc. code VSR95 Ed. 99.

- Air Ducts Electric Heaters with Explosion-proof connection head in ATEX configuration, with Finned- and Tubular heating elements suitable for installation in dangerous Environments, with connection head IP65 – E x-d IIB and IIC for temperature class T1-T6 II2G-ATEX for installation on Crude Oil Offshore Platforms, Air Conditioning units, HVAC units and (ATU) Air Treatment Units Systems.

- Certification UL/CSA (suitable for heaters designed and marketed for export to North-American countries U.S.A. and Canada)

- Certification EAC (suitable for heaters designed and marketed for export to Russia)

The wide range of our industrial electric heaters manufactured upon client’s order and standard, is recognized today by our historic and recent Customers, to be of excellent quality/price ratio.

Our experience gained on the sector during almost 50 years and our current organizational structure, are able to satisfy our Customers most different requirements. Our Technical Department adopts on a daily basis, sophisticated automated CAE/CAD design systems and the production division uses modern numeric control production systems, folding robotized systems, full annealing in controlled environment for an excellent stabilization of the thermal-insulating material and automated filling and gimping.

The continuous design and manufacturing techniques improvement, our marketing strategies and policies in Italy and abroad, developed through the years, combined to the high product quality, excellent service, reliability and client-supplier relation based on transparency, allowed us to count among our Clients, primary leading companies worldwide, in the machinery construction used in many industrial sectors of the economy, and to develop a marketing network at worldwide level.