Air and gas heat exchangers and control panels (secure area)

GENERAL CHARACTERISTICS:

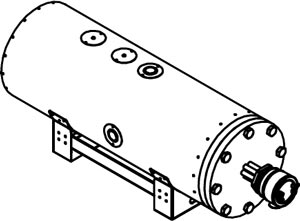

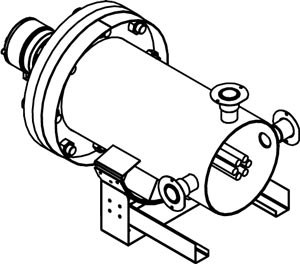

Electric heat exchangers are referred to as electric heaters installed on board a pressurized cylindrical container; are manufactured to meet the most varied industrial applications in the heating of gaseous fluids, whether they are air or gas mixtures.

This type of heaters guarantees high performance and efficiency in maintaining high volumes of gaseous fluids in forced circulation; the heating elements that make up the tubular bundle may mainly consist of U-shaped, eyebolts or torch-wound shapes.

This type of resistors is designed for horizontal and vertical installation, in the direct heating of forced air and / or gas, as well as for the indirect heating of fluids for the most unlimited use in the main industrial sectors.

Thermal exchange is guaranteed by the use of suitably designed seals (usually 50% or 75% diaphragms or laser cut spacers) to maximize the heat produced by electric resistors with reduced load loss (expressed in millimeters of water columns – mmH2O).

The use of high-quality materials within our production cycle enables our process electric heaters to reach high operating temperatures and a medium to long-term operating life.

|

|

USE

This type of heaters guarantees optimal thermal exchange, even in very compact dimensions, and at the same time, control the fluid temperature very precisely, especially if the power is controlled by a SCR (Solid Control Relais) control system.

To ensure the design of an efficient flush diving electric heater, you need to know the following technical parameters:

Electrical wiring is housed and hermetically sealed within one or more electrical wiring heads with IP55, IP65 / 67 protection rating.

The armored heating elements installed on board these special heaters are also drawn and positioned with a precise lay-out, so as to make the heat exchange optimal.

Each element is welded to TIG or silver alloy welded on unified DIN or ANSI flanges or on flange unity joints of variable size depending on working pressure and working temperature.

The skin temperature on the elements depends on the output temperature required by the specific application and the surface load (W / cm²) above, of course the type of fluid to be heated and its speed, measured in meters per second (m / s) or in cubic meters per hour (m3 / h).

The head of the electrical connections is the most stressed area of the application to which these heaters are subjected.

We are able to produce CE marked air heater processors, fully compliant with recent CEI and CENELEC standards.

This type of electric processor heaters is made of high quality materials for the heating tubing of carbon steel, stainless steel AISI304, AISI321, AISI316L, AISI316L S.S., Incoloy800, Incoloy825 and Inconel.

The pressurized tank housing the tube bundle can be made of Carbon Steel, AISI304, AISI316, electrically or extruded, or, alternatively, in special Superduplex SAF-2507 specialty material for marine applications.

The power can be concentrated in one or more power stages with the respective inlet inputs of the Gas, Metric, BSP, NPT or Gk pitch connections. also used for the independent power supplies of the thermoregulation devices installed on the heating heater.

TYPICAL JOBS:

CERTIFIED QUALITY PRODUCT

The entire production cycle of our air heat exchanger heat exchangers is subjected to the most rigid dimensional and electrical tests in accordance with our ISO 9001: 2008 certified quality management system and in full compliance with CEI / EN .

TECHNICAL DATA

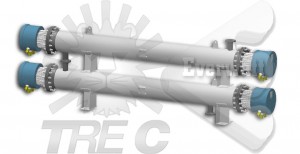

Depending on the specific temperature and the amount of air to be heated, it is possible to configure the design of the electric heat exchanger consisting of one or more pressurized (also suitably insulated) reservoirs connected in series with each other and one or more heads side by side or placed at each other end of the mantle as shown below:

|

|

|

This type of heat exchanger is suitably equipped with efficient thermoregulators (temperature control thermostats with adjustable temperature range, automatic or manual reset or, alternatively, skin safety thermostats with cut-out operation, PT100 thermal and / or thermocouples “J” or “K”), suitable for protecting the heater from overheating and any premature damage. On the board of the electrical wiring, according to the specific needs of the customer, the power inputs (NPT or GAS) are also sized according to the number of installed elements, the power and the hollow which determines the cable section .

ELECTRICAL CONTROL PANELS FOR HEAT EXCHANGERS FOR AIR (secure area)

On the customer’s specification and on the requirements of the plant on which the electric heater of our production (electric heat exchanger) will be installed, we make electrical control panels with various functions for controlling our heaters. These frames are suitable for both indoor and outdoor installations; complete equipment in every detail and technical feature, both in terms of power control and process control.

The extensive experience gained in the electric heating sector has enabled us to design, create and optimize effective process control solutions in various areas of application for safe installation in different countries, including extraUe, providing our customers with the commissioning service through our highly specialized staff.

Here are some of the most important features that we can supply on our electric boards:

SOME EXAMPLES: