GENERAL CHARACTERISTICS

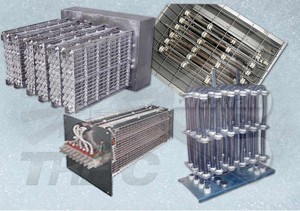

Electric bare-wire heating batteries are made by coupling a series of modules or bare wire heating coils, which are mounted on the air duct by means of galvanized sheet or stainless steel frames.

The (bare wire) resistive coil is composed of one or more resistance wires, either straight or suitably shaped, and fixed to insulating supports made of ceramic material.

The heaters are equipped as standard with protection grids, automatic reset thermoprotectors and connection cables. On request, the related electrical circuit can be supplied as well (i.e. contactor, switch, terminal board, etc.).

The resistive coil of the bare wire resistors can be arranged on one side only or on both sides, with the aid of metal supports whose function is to make the resistor structure more reinforced and compact.

The bare wire batteries are built exclusively with the use of top quality materials, which ensure the resistance wire a high estimated operating life (wire of FeCrAl material, NiCr and special alloys), especially under high thermal stress conditions due to continuous thermal expansions resulting from frequent intermittent ON/OFF cycles at high temperatures. Nevertheless, the materials used to support the resistive coils of these resistors too maintain the highest thermal insulation standards and are free from chemical reactions. Typically, they are coupled to ceramic or refractory supports of cylindrical shape crossed by channel sections suitable to house the resistive coils.

There are mainly two versions of bare wire heating batteries, namely:

They can also be easily equipped with on-board ventilation systems, if expertly coupled to connectors and fixing systems, as well as being connected to efficient temperature regulation devices.

TECHNICAL DATA:

Power supply: 1-phase / 3-phase

Standard supply voltage included in the range 24 – 440V, frequency at 50 – 60Hz.

MAIN ADVANTAGES:

MAIN USES:

Electric bare-wire heating batteries are widely used in all major sectors, such as:

SOME EXAMPLES: