GENERAL FEATURES:

The Ceramic band heaters, because of their multiple uses, electric heaters are made of thermal insulating dielectric insulating material (ceramic fiber) which are joined together inside of which is interposed a resistive circuit made of spirals of wire alloys special high quality, which makes them suitable for all heating applications in contact, for higher temperatures, being coated with a metallic structure or armor that protects against external shocks.

In relation to their application and the required temperatures, these Ceramic band heaters are able to better express their full potential.

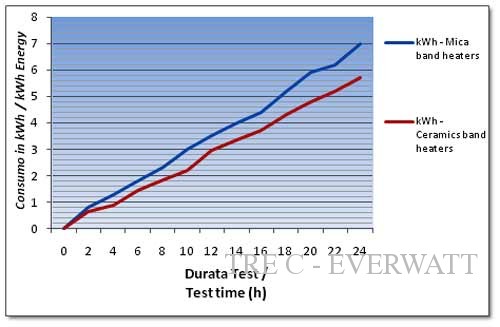

The quality of the raw materials used, as well as the experience and the extreme care with which we are assembled, make this type of electric heaters of proven efficiency and reliability. The ceramic fiber insulating thick 1 / 4 “, joined the resistive wire in high-quality steel alloys can withstand high temperatures provides an efficient heat transfer and energy savings of 25% compared to similar heaters without thermal insulation.pared to similar heaters without thermal insulation.

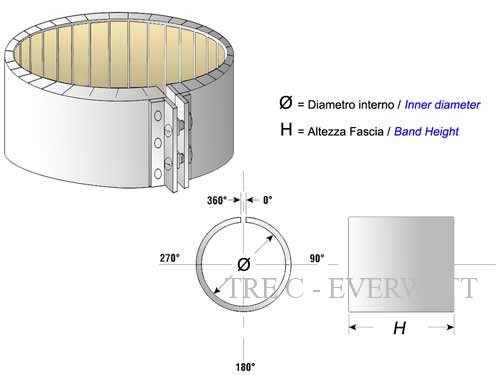

Made in various sizes, these resistors completely envelop the diameter of the cylindrical surface containing the fluid / material to be heated, positioned in direct contact with its surface, this provides a kind of radiant heating on the body to be heated, thanks to an optimal heat exchange and high surface density (W/cm2).

This graph shows the energy saving of around 20% obtained when using a ceramic band heaters than with mica insulation. This result is the result of a laboratory test after 24 hours of continuous work.

Advantages:

rements is also possible to create multi-distribution circuit, or where the total power required on-board barrel is divided between several heaters heaters connected to each other.

rements is also possible to create multi-distribution circuit, or where the total power required on-board barrel is divided between several heaters heaters connected to each other.Uses:

The rules for the application of a resistance band are a function of media type and temperature that will host that will endure.

Typical applications of this heater are:

Technical specifications:

PRODUCT QUALITY CERTIFIED

The entire production cycle of ceramic band heaters is subjected to rigid controls dimensional and electrical tests in accordance with regulations of our Company Quality System certified to ISO 9001:2015 and in full compliance with the requirements of current standards IEC / EN.

The various operating temperatures require different combinations of type of external and internal insulation shield, which you can choose among those, the following listed:

The construction of an electrical

| Operating temperature | External sheath | Internal insulation | Electric contacts finishing |

| 100° C | Anodized iron | Micanite | Cables/ Pins/ Clamps |

| 200° C | Anodized iron | Micanite | Cables/ Pins/ Clamps |

| 300° C | Anodized iron | Micanite | Cables/ Pins/ Clamps |

| 400° C | AISI 304 | Ceramic/Micanite | Pins/ Clamps |

| 500° C | AISI 321 | Ceramic | Pins/ Clamps |

| 600° C | AISI 321 | MGO/Ceramic | Pins/ Clamps |

| 700° C | AISI 321 | MgO | Pins/ Clamps |

The combinations referred to above are those commonly used in various applications, the temperatures specific for each type.

Improper use of the heater with respect to the initial design release the manufacturer from any liability.

USEFUL DESIGN DATA

Ceramic band heater requires some knowledge of the technical data essential to the design:

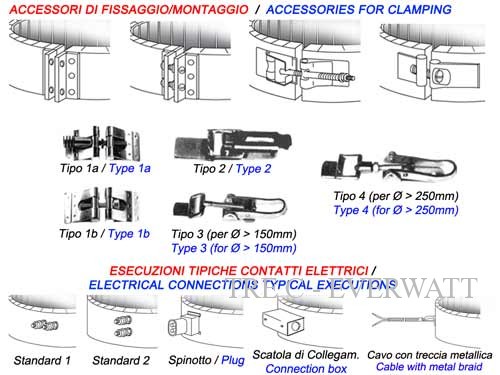

TYPE OF EXECUTION (Electrical contacts and attachment / mounting system)

The ceramic insulation of these electric band heaters band in can be realized taking into account two different parameters:

Standard Resistors Catalogue

This type of ceramic band heaters can be built to customer specifications is that in the standard version, which we have a warehouse ready for the type of power, voltage, sheath diameter and type of finish.

SOME EXAMPLES

For further details please have a look at the section “Download Area“

or send us the details of your inquiry by fulfilling our online “Quotation Request Form“