GENERAL CHARACTERISTICS:

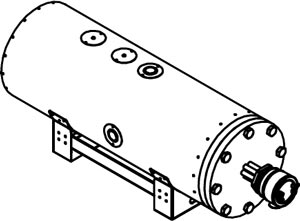

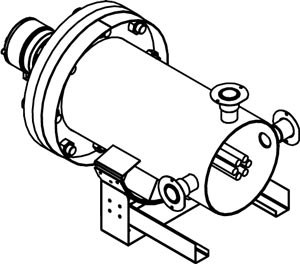

The flanged or on-cap electric heaters (threaded fitting) installed inside a pressurised cylindrical, insulated or non-insulated container) are called process heaters or electric heat exchangers manufactured to satisfy the most different industrial applications for fluids, air or gas heating sector.

This heaters typology grants high performances and efficiency in maintaining the temperature of high volumes of fluids under forced circulation (water, industrial oils such as fuel oil or thermal oil, gas and air).

The heating elements forming the tube-bundle can mainly take up U-shapes or eyelet shape folds.

They can be designed for horizontal or vertical installation, for fluid direct heating intended for countless uses, in the main industrial sectors. As optimal solution in heating fluids under forced convection, these products use immersion electric resistors into direct contact with the fluid to be heated.

The heat exchange is granted by the use of separators specifically designed to exploit at the best the heat produced by the electric resistors.

The first quality materials use within our production cycle allows the process electric resistors manufactured by us, to reach high operating temperatures with a medium-long term useful operative life.

|

|

USE

This heaters typology grants an optimal heat exchange, also in very compact dimensions and, at the same time, it allows to control the fluid outlet temperature with great precision, especially if the power is managed by a SCR (Solid Control Relays) control system.

Outlet Temperature (of the thermally treated air flow) and surface Density (W/cm ²), in addition to the fluid typology and speed (air or gas) in metres per second (m/s) are the variables determining the elements surface temperature installed inside the air duct heater.

In order to grant the product suitability for being installed in dangerous environments subject to explosion risk , the electric connections are enclosed and hermetically protected inside one or more electric connections housings or heads for use in explosive environment.

The immersion heating elements installed inside these special heaters are designed and positioned with a specific layout, in order to optimize the heat exchange.

The surface temperature on the elements depends on the outlet temperature requested by the specific application and from the surface load (W / cm ²) allowed by the same application, besides naturally to the fluid type to be heated and its speed, measured in metres per second (m/s) or in cubic metres/hour (m3/h).

The electric connections head is the most stressed zone by the dangerous application these heaters are subject to. Each electric heat exchanger with explosion-proof head can have one or more ATEX certified heads and therefore suitable for being used in explosive environment.

We are able to manufacture process heaters with ATEX certified explosion-proof head (certified for use in explosive environment Eex-de, Zone 1 and 2 – II2G/D ATEX) with CE marking, made in full compliance with CEI and CENELEC regulations in force.

This electric heaters typology is manufactured with high quality materials such as carbon steel, stainless steel AISI-304, AISI-321, AISI-316 and Incoloy800 (heating elements tube) and in Galvanized Steel FeZn or in Stainless Steel AISI-304/316 (limitedly to the structure-frame containing the elements and the electric contacts IP65-IP66 protection head and to the power inlets of the thermoregulation devices (NPT or GAS type) power stages.

Typical uses

CERTIFIED QUALITY PRODUCT

The entire production cycle of our electric heat exchangers for industrial use is subject to the strictest dimensional checks and electric tests in compliance with the standards set forth by our own ISO 9001:2015 certified Corporate Quality System, and in full compliance with the CEI/EN requirements in force.

TECHNICAL DATA

This heaters typology consists of a tube-bundle made of various heating electric elements of different diameter, normally folded in U or eyelet shape, perpendicular to the electric contacts outlet. Each element is TIG-welded or braze welded in silver alloy on DIN, ANSI unified flanges, or on flanged fittings of non-unified shape, of variable dimension, based on the operating pressure and operating temperature.

The electric connections section is enclosed inside housings or carbon steel or stainless steel IP55/IP56 standard heads, or inside specific ATEX explosion-proof heads, suitable for use in explosive environment.

| ATEX Temp. Class | ||||||||||||

| ‘T6′: 85°C | ‘T5′: 100°C | ‘T4′: 135°C | ‘T3′: 200°C | ‘T2′: 300 | ‘T1′: 450°C | ||||||||||||

| Cold zone Lg. | A | B | A | B | A | B | A | B | A | B | A | B |

| 300 mm | T6 | X | T4 | X | T3 | X | T3 | X | T2 | X | T2 | X |

| 250 mm | T6 | X | T4 | X | T3 | X | T3 | X | T2 | X | T2 | X |

| 200 mm | T6 | X | T4 | X | T3 | X | T3 | X | T2 | X | – | |

| 150 mm | T6 | X | T4 | X | T3 | X | – | – | – | |||

| 100 mm | T6 | X | T4 | X | T3 | X | – | – | – | |||

| 0 mm | T6 | X | – | – | – | – | – | |||||

| Working Temp. | 0°C | 100°C | 150°C | 200°C | 250°C | 300°C | ||||||

| Legenda:A = Temp. ClassB = Ex-proof head Temp.-proof allowance | (X)= Yes | (–)= Not | ||||||||||

Equipped with efficient thermal regulation devices (control thermostats with adjustable temperature scale, with automatic or manual reset or, alternatively, surface safety thermostats with intervention cut-out, thermistors PT100 and/or thermocouples “J” or “K”), suitable for protecting the heater from overheating and possible premature damage. Inside the electric connections heads, based on the customer specific exigences, also the electric power inlets (NPT or GAS) are properly dimensioned, according to the number of elements installed, power and amperage determining the cables’ section.

The electric resistors type surface load (W/cm2) is specifically decided from time-to-time, based on the use conditions and type of fluid to be heated; in addition to these factors, the maximum operating temperature and operating environment are also variables influencing directly the sheath material type choice, the tube-bundle of these heaters will be manufactured with (Carbon steel, stainless steel AISI304, AISI309, AISI 321, AISI 316L, Incoloy800-825, Inconel 600 or Titanium).

SURFACE LOAD (W/cm2) SELECTION GUIDELINE:

SOME EXAMPLES: