Main Features

The PT1000 thermo-resistance are suitable for temperature-sensitive elements to measure the temperature given their particular sensitivity, precision and reliability.

The temperature measurement by means of thermoresistors is based on the characteristic, common to all conductors and semiconductors, of modifying its electrical resistance as the temperature changes.

The PT1000 sensor has an ohmic value of 1000 at a temperature of 0°C.

Unlike the more common PT100 sensor, the higher signal of the PT1000 allows greater precision and therefore avoids the presence of the third wire needed to compensate the ohmic value of the cable.

Available in any shape, size and material, the PT1000 probes are commonly applied in all those application fields where the maximum working temperature is ≤650°C (1200°F).

ADVANTAGES:

Typical applications

PT1000 probes are widely used in the following areas of use:

Technical Data

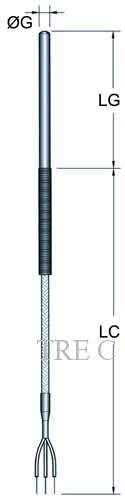

A standard type PT1000 thermal resistance is equipped with a cylindrical AISI304 sheath, suitable for measuring temperatures and general adjustments. This model presents the output from the sheath of the cable protected by a stainless steel spring, which can be housed within one or two sensing elements which can be connected to 2 wires.

Also suitable for use in diving, the PT1000 can also be supplied complete with connection head, suitable for measurement and control of generic systems, by mean of a threaded sleeve welded directly on the (fixed) or by special joints or flange sliding compression. The electrical connection is made within the connection head through a ceramic terminal block. On request they can be alternatively provided with an analog output 4-20 mA.

The technical parameters necessary for the design and identification of the PT1000 model best suits the needs of the customer are:

QUALITY CONTROL

All our PT1000 are thoroughly subjected to the most stringent tests of quality and safety, by means of automatic machines and in full compliance with applicable regulations and international standards.

Made according to international standards EN60751, under which it is used with platinum temperature coefficient alpha = 3.851 E-03,

platinum resistance thermometers (RTD Platinum) can alternatively be built to customer specifications in accordance with other standards such as, for example, JIS C 1604, etc. …

The EN 60751 provides resistance thermometers with a nominal value at 0°C (Ro) between 5 and 1000 ohms, but the values most commonly used are 100 ohms, 500 ohms and 1000 ohms.

The relationship between the resistance at temperature t ° (Rt) and the resistance at 0 ° (Ro) is as follows:

in-200°C / 0°C –> Rt = Ro [ 1+At+Bt²+C ( t-100 ) t³ ]

in 0°C / 850°C –> Rt = Ro ( 1+At+Bt² )

where: A = 3,9083E-03 / B = -5,775E-07 / C = -4,183E-12

The accuracy classes of platinum resistance thermometers are related to temperature and are normalized so:

Class AA = 0,1+0,0017* | t | ( °C )

Class A = 0,15+0,002* | t | ( °C )

Class B = 0,3+0,005 | t | ( °C )

Class C = 0,6+0,01 | t | ( °C )

The temperature ranges of validity of the tolerance classes above are listed in the table below.

All resistance thermometers with higher tolerance to class B should have a three-or four-wire.

SOME EXAMPLES: